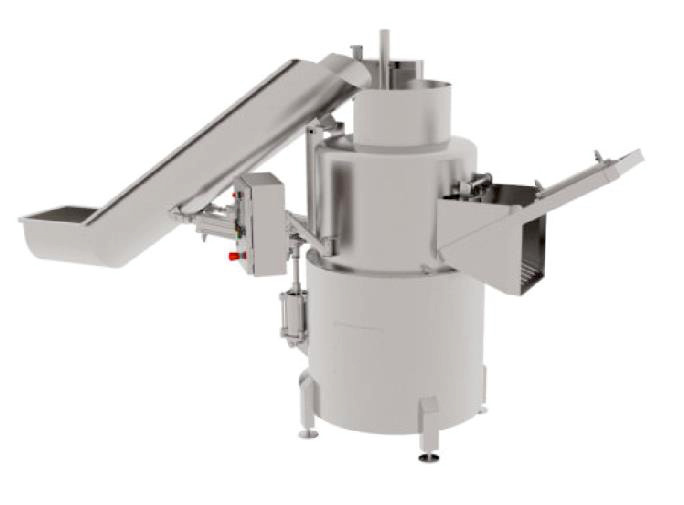

BW-WCL centrifuge for degreasing of cattle rumen and omasum

The product is processed in the upper part of the centrifuge by turning a disc with abrasive coating and special shaped bumps.

In the basic set up of the centrifuge, the product is loaded and unloaded manually.

Centrifuges are equipped with a washing time regulator, which allows to regulate the time of product processing and a frequency converter to control the rotational speed of the disc.

Optional machine equipment (consultations with the Customer):

- automatic lift - pneumatic tilting device,

- automatic lift – mast tilting device,

- automatic cover for feeding,

- automatic unloading of products,

- automatic electronic water mixer,

- automatic tilting of the working part of the machine.

Material: AISI 304 stainless steel.